Quality Assurance

As a world-class product provider, we maintain a continual focus on a high level of customer satisfaction.

Our quality control process starts with compliance to QS-9000 Quality Systems requirements, but also encompasses careful attention to the basics, providing a skillful and committed team, using only state-of-the-art equipment, and sustaining an exceedingly organized and clean facility.

Our quality assurance approach is anchored by a continuous product and process improvement program coupled with our practice of close contact and prompt response to customer demand.

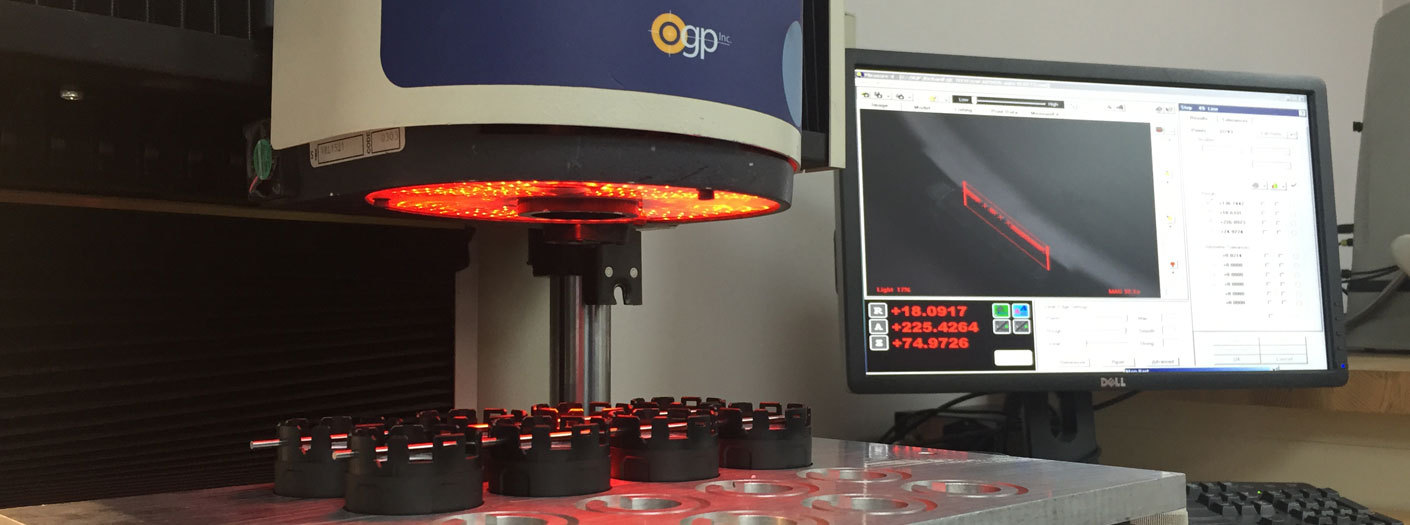

Optical Gaging Microscope – an automatic multisensor measuring system

Optical Gaging Microscope – an automatic multisensor measuring system

QC Capabilities

We maintain a fully staffed Quality Assurance Department with the following capabilities:

- Full process documentation–APQP and PPAP submittals (PTMEA, PFD, control plans for all jobs)

- Complete in-house dimensional layout capability

- Material moisture analyzer and melt flow testing

- Custom inspection fixtures

- Statistical process monitoring–charting and capability analysis on all critical measurements as necessary

- Process capability analysis

- Advanced material testing via Trace Laboratories

Training and Technology

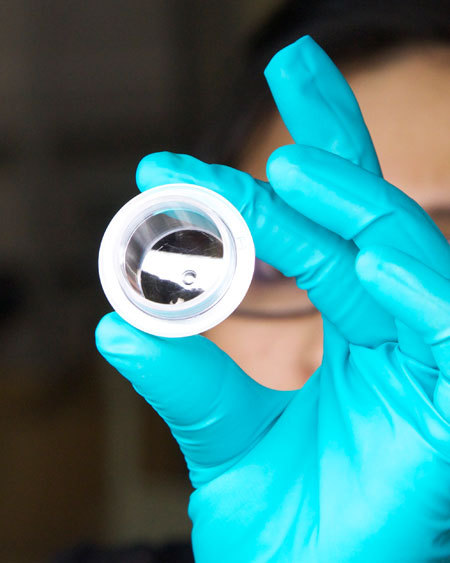

Our certified quality technicians and operators have the finest technology available to assist them in maintaining our high standards. Examples include:

- QA metrology lab with CMM (Coordinate Measuring Machine) and video CMM with Vision System

- Complete material lot traceability

- Spectro Photometer for color measuring

- Force gauges for measuring tensile strength

- Trained and skillful quality inspector

- Continuous improvement and training