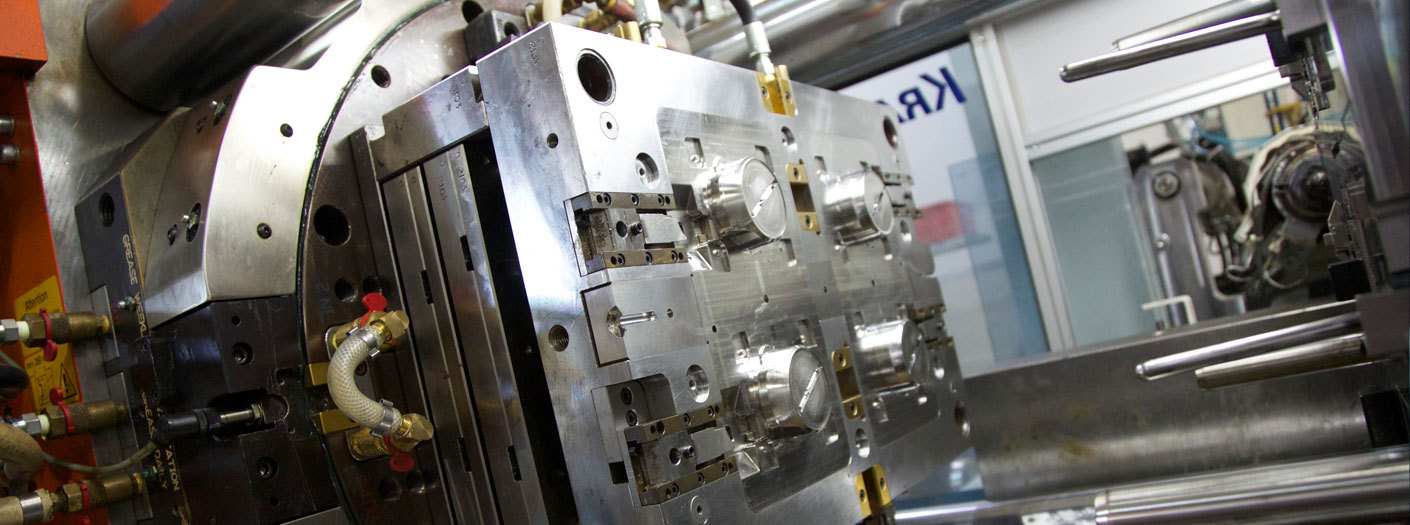

Injection Molding

Customize your components: Our wide range of molding capabilities removes limitations found at traditional molding suppliers.

Foreman Tool's molding department has 22 presses capable of semi-automatic and full-automatic mode working 24/7 with controlled scheduling. Our 28T through 500T molding presses include auxiliary equipment along with robotic capabilities. We run multiple cavity molds producing 466 different parts.

Certified toolmakers carefully maintain and repair tools onsite–there is no downtime to delay delivery of your components.

Molding Options

Top of the line equipment and highly trained technicians mean that we can apply a wide range of molding techniques to your needs. Process capabilities and equipment include:

- 28 to 500-ton molding presses with auxiliary equipment and robotic capabilities

- High cavitation production molds

- 1 cavity – 16 cavity molds

- Decorative, textured and diamond-finished parts

- Pad printing hot runner technology

- Assembly

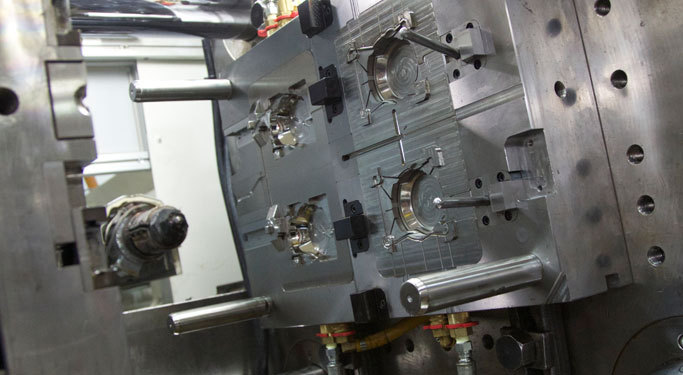

Complex Molding Applications

Along with standard single-shot procedures, we are experts at the most complex molding combinations such as two-shot, insert molding, and more.

Single shot molding

- Hot runner

- Thread forming

- Valve gates

- Hydraulic cores

- Insert molding

Two-shot molding (90T through 500T)

- Back side rotation

- Index plate rotation

- Sequential

- Robot transfer molding

- Insert molding

Packaging to Protect Your Product

- Tooling and product qualification and process validation

- Continuous process monitoring and statistical process control

- Detailed documented manufacturing processes and inspection requirements

- Climate controlled environment

- Skilled and trained employees in all positions

Automation

- Robotic handling with servo robots

- Design and build robotic end of arm tooling in house

- Portable vision systems detection/verification

Secondary Operations

- Pad printing

- Assembly

- Subcontracted chrome plating